Applications

Marine

Efficient, adaptable, and cost-effective. Our patented efficiency PACKs enable you to produce zero-carbon electricity from the waste energy of your combustion engines, such as exhaust gas and cooling water. With a streamlined circulation system, reliable industrial components, and smart control algorithms, they seamlessly sync with your ship’s grid without needing a frequency drive, ensuring optimal use of waste heat in your operations, anywhere in the world.

Applications

Marine

Efficient, adaptable, and cost-effective. Our patented efficiency PACKs enable you to produce zero-carbon electricity from the waste energy of your combustion engines, such as exhaust gas and cooling water. With a streamlined circulation system, reliable industrial components, and smart control algorithms, they seamlessly sync with your ship’s grid without needing a frequency drive, ensuring optimal use of waste heat in your operations, anywhere in the world.

EFFICIENCY PACK

EP M 050.100

Specifications

Application: marine (e.g. ships, new builds and retrofits)

Up to 100 kW net electric maximum rated output

Input power: 560–1,100 kW thermal (e.g. >1 MW engine flywheel power, per module)

Heat sources: Exhaust gas (max. 600 °C), saturated steam (120–180 °C),

thermal oil (120–180 °C), warm water (e.g. from jacket cooling, 75–109 °C

Dimensions: 1,180 x 1,400 x 1,982 mm (W x L x H)

Industry & Power Plants

Our technology enhances energy efficiency in industrial operations, ensuring optimal resource utilization. It also reduces CO₂ emissions and significantly lowers electricity costs, helping you meet both financial and environmental objectives. With a plug-and-play design, our systems integrate seamlessly into existing industrial processes with minimal disruption. Additionally, our solution is versatile, compatible with steam, thermal oil circuits, and exhaust gas systems, making it suitable for a wide range of applications.

Industry & Power Plants

Patented, flexible designs ensure straightforward installation, with standardized industrial components enabling quick setup and seamless integration into existing infrastructure. Intelligent control algorithms optimize performance and minimize maintenance needs, ensuring consistent operation with minimal intervention. Built for durability, these systems require little upkeep, providing the benefits of clean energy with minimal effort.

Industry & Power Plants

HeatVolt technology converts waste heat into clean, carbon-free electricity, enhancing energy efficiency and sustainability in power plants. With world-leading conversion efficiency, it enables power producers to integrate reliable, renewable power into their energy mix without relying on weather conditions. The modular and scalable design allows for seamless expansion, maximizing clean energy output and helping power stations meet critical environmental targets.

Geothermal

Geothermal power harnesses the Earth’s natural heat in geologically active regions, providing a constant supply of clean electricity around the clock. By targeting lower-temperature resources, this technology significantly expands the number of locations that can utilize geothermal energy, transforming it into a viable baseload energy source for communities worldwide. The system’s modular design allows for easy scalability and offers operational flexibility, reducing resource risks and enhancing the likelihood of project success.

Applications

EFFICIENCY PACK

HeatVolt 200 EP 150.200

Applications: Industry & Power

Input power: 2 MW thermal (per module)

Heat sources: fluid heat sources above 80 °C (ideal 140 °C), gaseous heat sources above 150 °C Electric Output: Up to 200 kW net electrical output

Dimensions: 12,2 m x 2,5 m x 2,9 m (W x L x H)

EFFICIENCY PACK

HeatVolt 100 EP 150.100

Applications: Industry & Power

Input Power: 500 to 1,200 kW thermal per module

Heat sources: fluid heat sources above 80 °C (ideal 140 °C), gaseous heat sources above 150 °C

Electric Output: Up to 100 kW net electrical output

Dimensions: 6.1 m x 2.5 m x 2.9 m

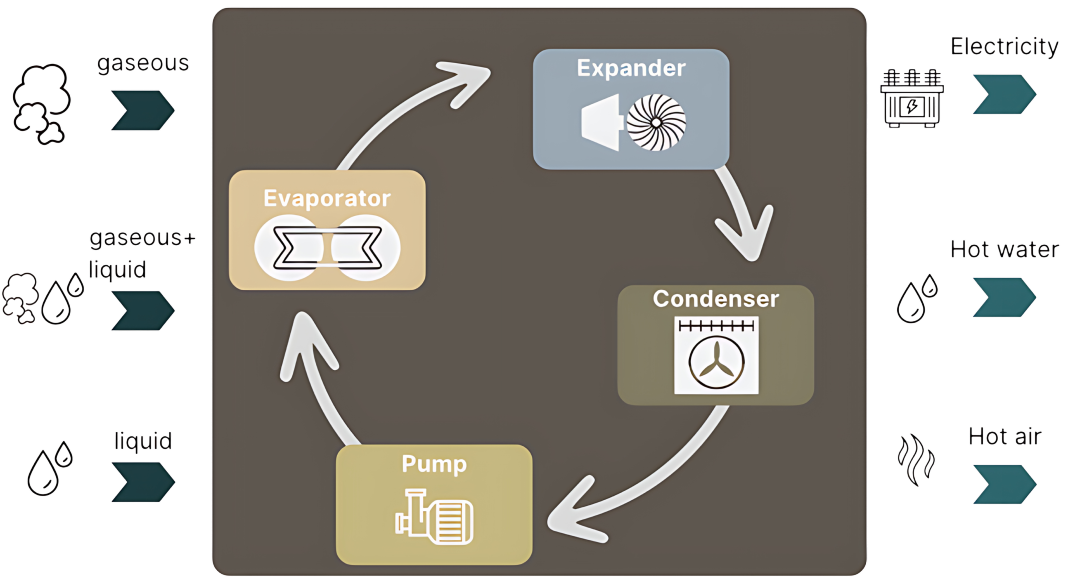

The process begins with the evaporator absorbing heat and transferring it to the pressurized working fluid.

1

This heated fluid then moves to the expansion machine, where it vaporizes and drives the machine to generate electricity through the attached generator.

2

Following this, the fluid condenses in the condenser, releasing residual heat into the air.

3

Finally, the liquid working fluid is pressurized by a pump, completing the cycle and allowing it to start again.

4

References

+ 600

units sold

6 million

operating hours

140.000 tons

CO2 emissions saved

Artix Energiesysteme GmbH

Gutenbergstraße 14

DE-72175 Dornhan

Customer Service

+49 (0)7455 9474816

info@artix-energysystems.com